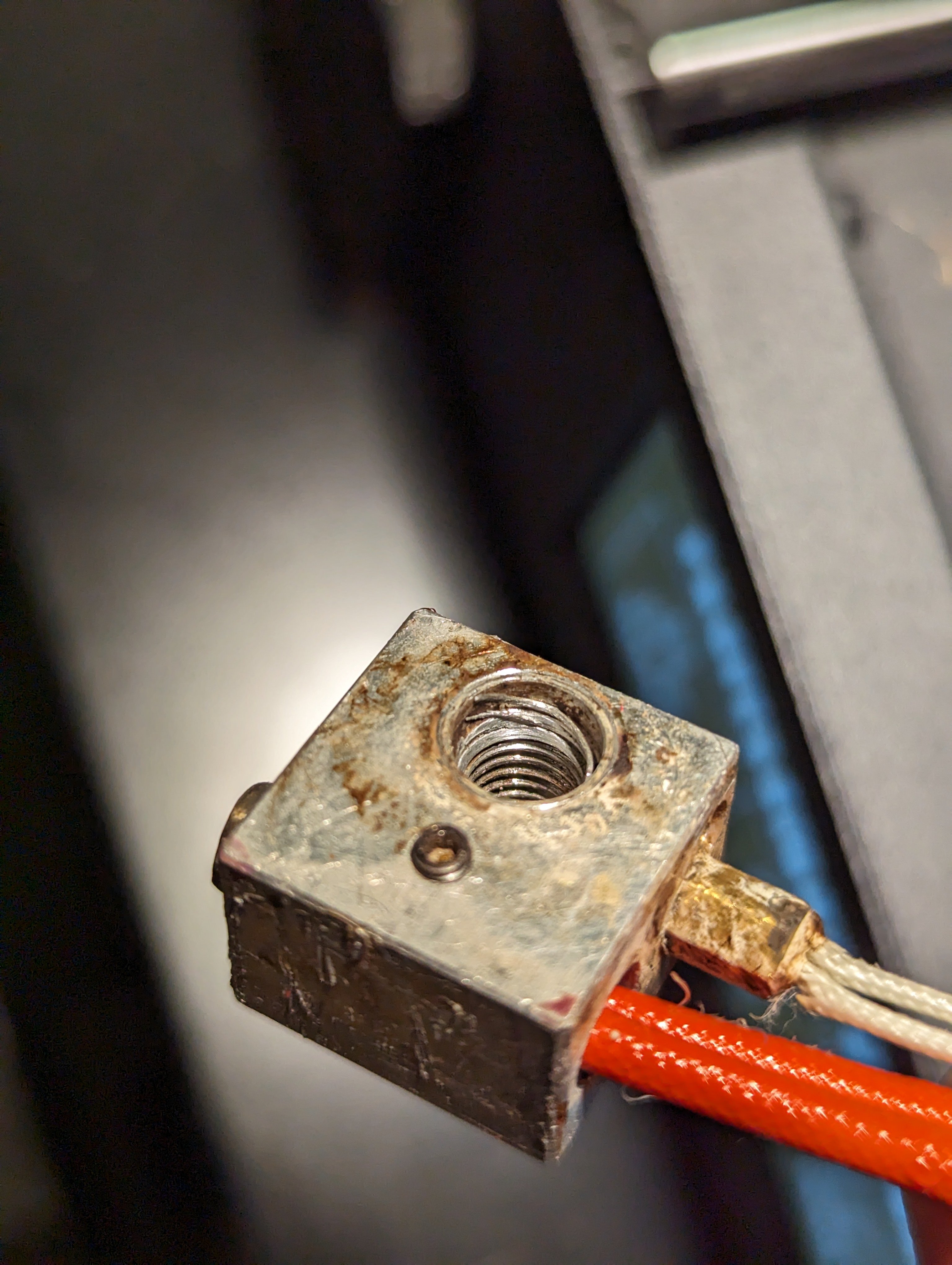

From the pic it looks like cross threading rather than over tightening. Always makes sure it threads smooth before you start tightening

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

It felt like it was in there fine to me, but maybe not.

maybe it's hotend upgrade time then

Been there before. Thankfully, replacement blocks are pretty cheap.

Yeah, I've already spent like $60 trying to help a guy save $10. What's another $20 on the pile? Lol.

I have a socket and extension I keep by the printer which fits the nozzle. That way I can screw it in by hand while hot, still easily feel if something is binding, and I don't even have to burn off my fingertips.

Good idea, I'll give that a go.

Did the same with Trianglelab Dragon. Damaged the heatbreak as well when disassembling the hotend. Now I own a 1.8Nm torque wrench..