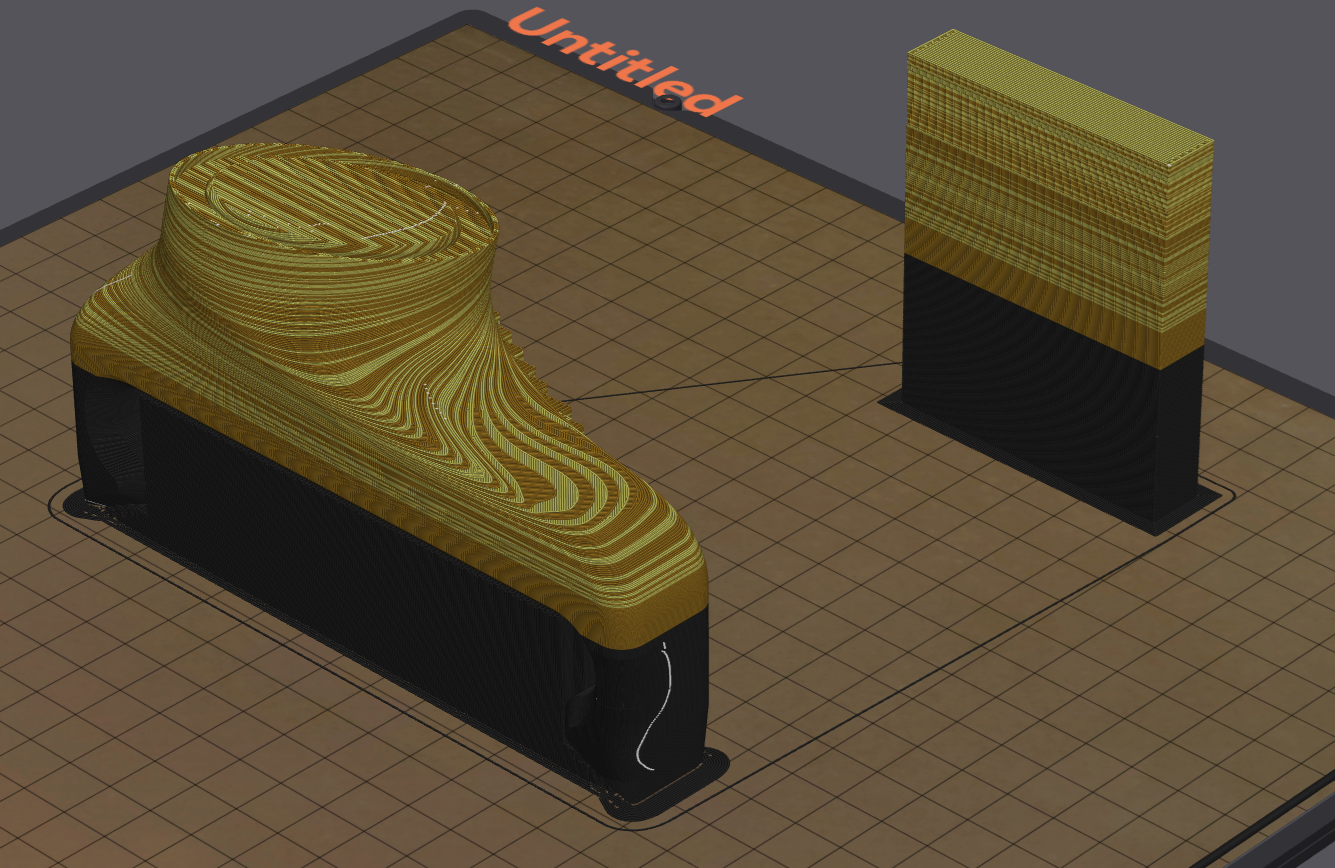

10/10 would grain

3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: [email protected] or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

When the comment is better than the post 😅

cool new extremely innovative home-made project vs low effort shit post

Sanded and assembled!

Magnifique!

That'd a cool idea and it looks really good. I'll have to try this for myself!

Wow!

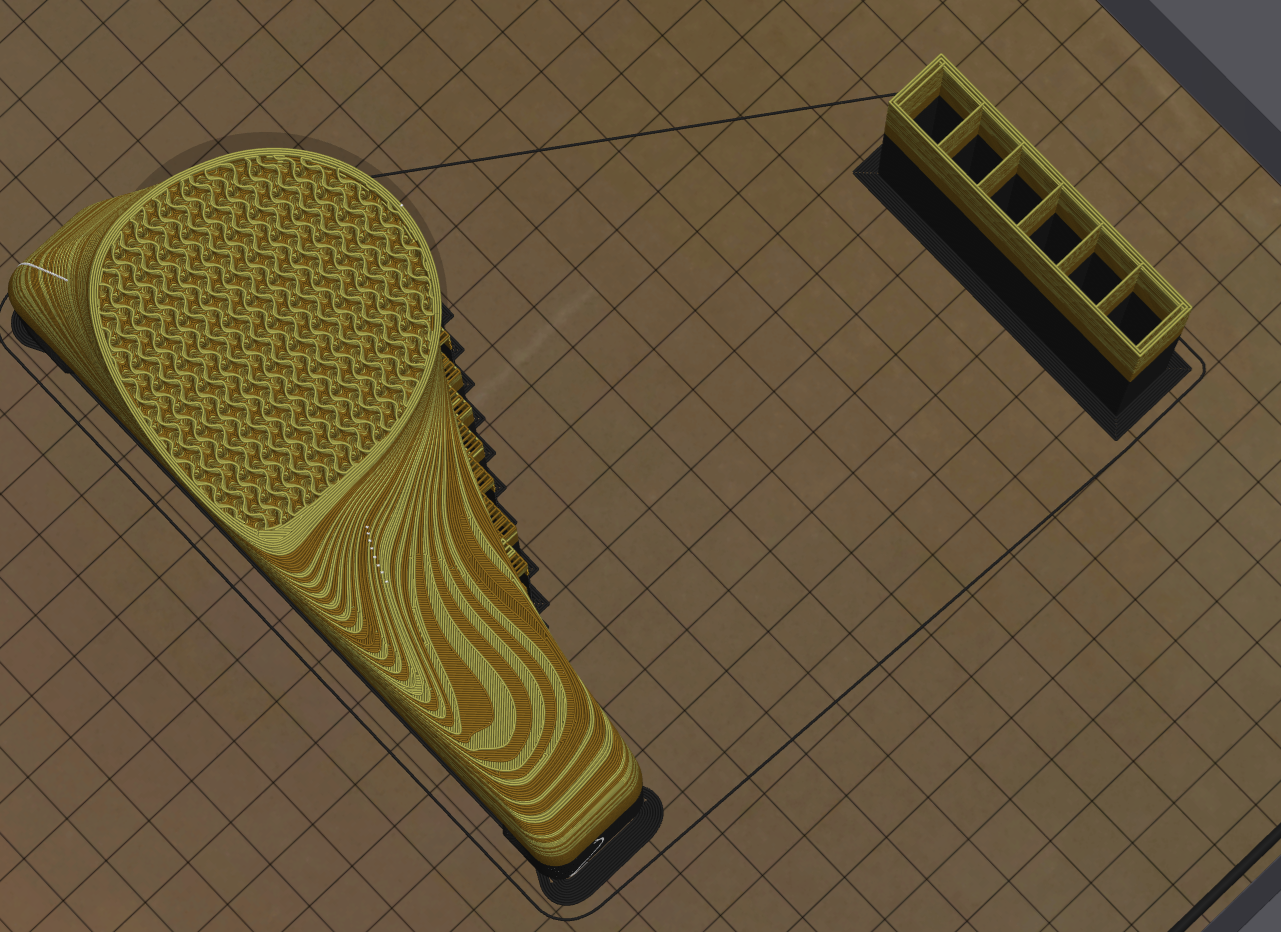

How much purge for something like this?

I'll check the slicer again but it was really small. Most of the purge went into infill instead. Maybe like 5 grams?

I had my purge values low to encourage blending of the colors. I might try using 0 for purge volumes next time to encourage more natural blending.

What slicer is it ? I will check if it is possible to set no purge at all in BambuStudio - since I have an AMS lite.

It looks feasible with a purge multiplier set to 0. https://forum.bambulab.com/t/setting-an-unbeatable-record-no-flush-at-all/51052/4

Orca :)

It's pretty similar to bambu

purge tower was pretty hollow

That's beautiful and extremely creative. I should fix my printer.

Do it!! And thank you!

Do you think printing without purge would make it look better? Or would it just blend into an medium brown

I think better, if there was always a little bit of leftover filament the pattern will be more random I think. With more gradual gradients

I'd love a 3D chameleon for my printer, but their shipping rate (I live in EU) is absolutely insane and unreasonable since they don't even handle import and taxes for that price.

With Sunlu's new filament joiner coming out, I might give this a try by splicing segments of different browns together into a big roll. It's a very near concept, and your print looks amazing!

That's a great idea! Would be such a faster print too

Gist time I sliced something for my AMS lite I was flabbergasted by the increase in printing time and waste.

For those unaware, since you're often having 4 filament changes per layer, each of which take about a minute, a 1hr mono-fillament print can suddenly turn into a 36-hr print with 5-10x more filament being purged than ends up in the model.

It's really cool, but super wasteful.

But you can strategize to minimize filament changes by splitting up a model and stacking it to minimize filament changes per layer. This one only took about 8 hours.

One reason I love the 3D chameleon is that it is easily modified in how it operates.

I have mine doing color changes at 20 seconds! It shaves many hours off of some big 4 color prints

I always Purge to infill and if there is a lot of purge material in the block I will add an object that is printed using the Purge. Something that I don't mind being stripey

What annoys me and I don't entirely understand is the purge tower. If I purge to infill or another object, why am I still having to build this dumb tower? If you choose to disable the tower, it disables the purge to infill option.

If the infill is enough to take up the entire purge volume needed to get rid of the previous color, then you are right.

Most of the time there are sections where there is not enough infill to purge what it needs to though

Since it's not a good idea to extrude filament into open space, it has to build up a structure for that later Purge. That's why it seems to make a hollow pointless Purge Tower sometimes.

Another factor is the minimum Purge amount. I think that is set in the filament settings. By default it is not zero, meaning it will always create the tower no matter what, though it might be really skinny.

If you add objects that will be created from The Purge material you should see that Purge Tower get smaller when you reslice, or at least less dense

ooh that's clever

Ah, I was trying to understand what MMU was. Then I realized off of those ridges that this was a 3D printed model. I was looking at the "marbling" and imaging it was some sort of putty or something akin to sculpey. It looks both groovy and comfy and you did a great job =)

Thanks!

Yeah, you guys always amaze me. On account of being able to model things spatially in CAD-esq software. It's a skill I never picked up on, and one that I really enjoy seeing in practice =)

Reminds me! I took a video of the timeline playthrough for the design process.

Thanks btw! It took me a few years to get efficient with CAD being self taught. Still learning

That's brilliant. What nozzle diameter and layer height did you use?

Thank you! Standard 0.4mm nozzle, 0.2mm layers

One of those two filaments is wood fill right? Do you ever get clogs with the 0.4 nozzle?

Absolutely, I was going to use a lighter shade of wood it kept clogging on me. Do I switched to the light brown pla. I think moisture is a big component in that too

You might try a 0.6mm nozzle, I know some manufacturers recommend >0.4 for filaments with filling in them.Very cool project though, you're giving me some ideas.

Yeah I might try that next time. I have .8 and 1.0 too, but too lazy to keep swapping 😂

I feel it. Those quick-swap nozzles are pretty appealing. Every time I swap a nozzle on the bambu I literally swap the entire hotend and unplug 3 delicate connectors. I'm worried they'll break after a couple dozen swaps.

I couldnt do it! I bought a pack of volcano nozzles for dirt cheap in all sizes, volcano is forever!

this is cool!

Be careful with PLA in your car, it will probably deform in the sun.

For sure! Luckily I park in an underground garage, so my car interior never really gets over 90

I have some PC just in case it does warp

That looks great!

Pretty cool!